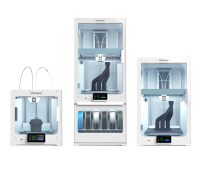

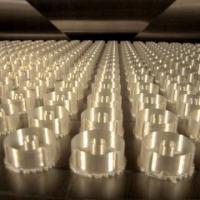

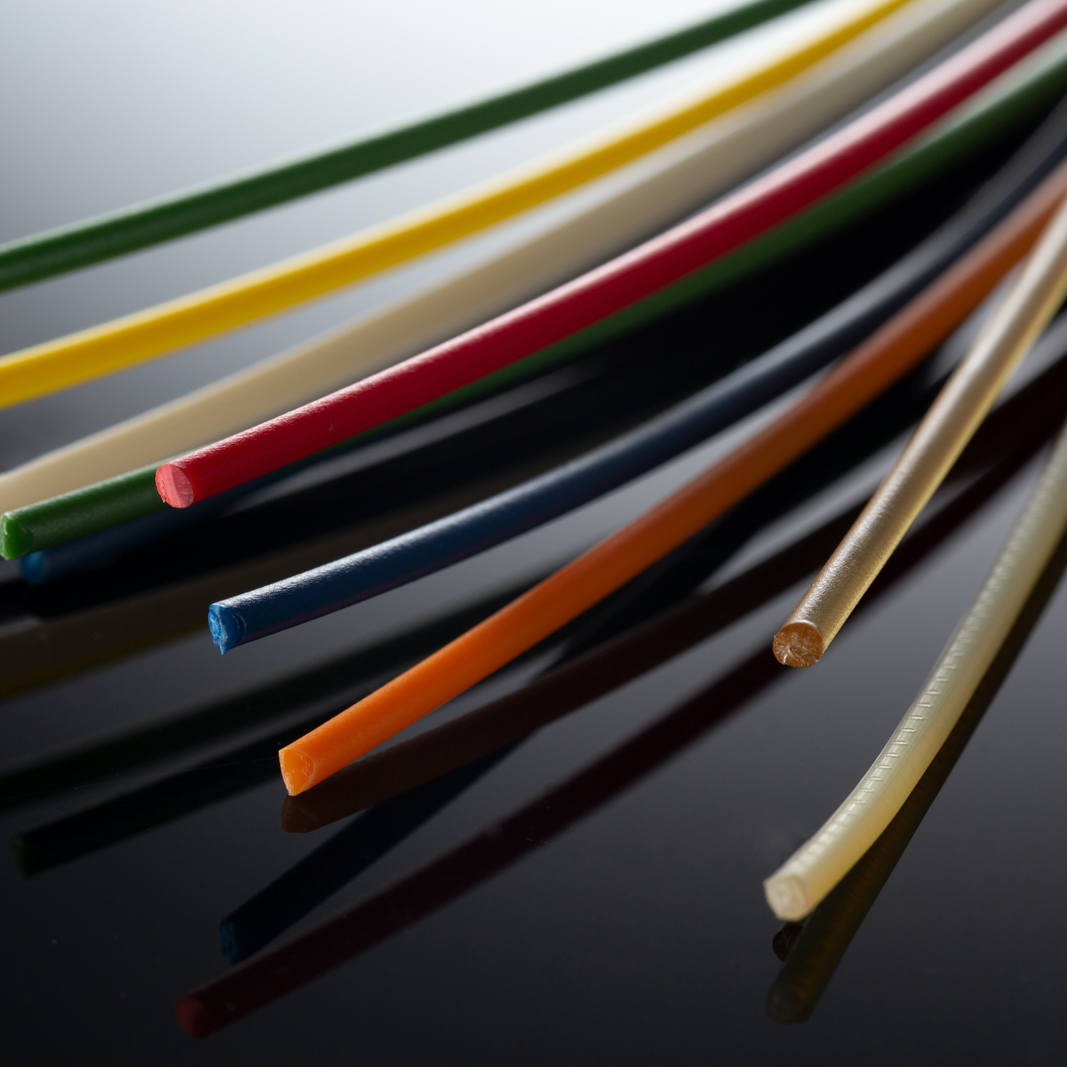

Kunststoffen FDM

> 15 jaar ervaring

Ervaring, kennis en klanttevredenheid zijn dé bouwstenen van ons bedrijf

Distributeur voor BENELUX

Uw lokale Benelux-partner met service-activiteiten en kantoren in de hele regio

Ga voor de beste deal

Financieringsmogelijkheden voor elke gelegenheid (renting, leasing, trade-in)